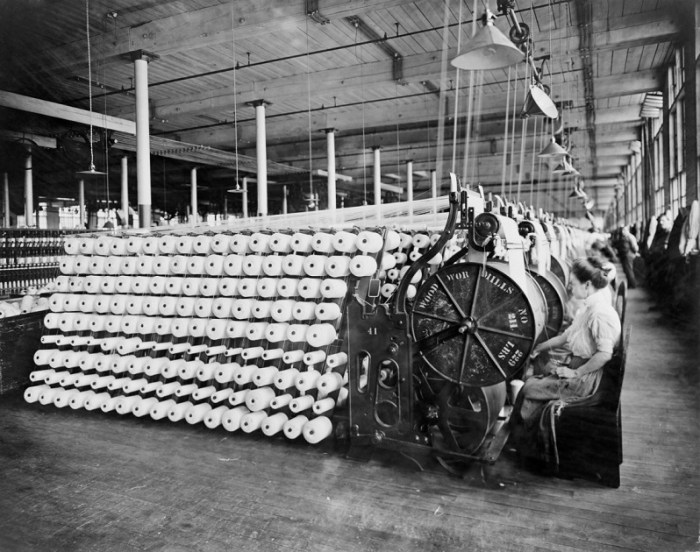

Embark on a journey into the realm of production revolution by blessing of gods, where technological advancements and innovative methods have orchestrated a transformative symphony, reshaping industries and propelling economic growth.

This revolution has unleashed a torrent of innovations, from the relentless march of automation to the agile embrace of lean manufacturing, leaving an indelible mark on production processes worldwide.

Technological Advancements: Production Revolution By Blessing Of Gods

The production revolution has been driven in large part by technological advancements. Innovations in machinery, automation, and computing have transformed production processes, leading to increased efficiency and productivity.

One of the most significant technological advancements in recent times is the development of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These systems allow engineers and manufacturers to design and create products digitally, which can then be directly translated into production instructions for automated machinery.

Another important technological advancement is the development of robotics. Robots are now used in a wide range of manufacturing processes, from welding and assembly to packaging and shipping. Robots are capable of performing repetitive tasks with precision and speed, which can significantly increase productivity.

Specific Technologies that Have Revolutionized Production, Production revolution by blessing of gods

- Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems

- Robots

- Automated guided vehicles (AGVs)

- Industrial Internet of Things (IIoT) devices

Innovations in Production Methods

In addition to technological advancements, the production revolution has also been driven by innovations in production methods. These methods include lean manufacturing, just-in-time inventory, and agile development.

Lean manufacturing is a production method that focuses on eliminating waste and inefficiency. It involves using a variety of tools and techniques to streamline production processes, reduce inventory levels, and improve quality.

Just-in-time inventory is a production method that involves producing only the products that are needed, when they are needed. This method helps to reduce inventory costs and improve cash flow.

Agile development is a production method that involves breaking down large projects into smaller, more manageable tasks. This method allows teams to be more responsive to change and to deliver products faster.

Advantages and Disadvantages of Innovative Production Methods

Lean Manufacturing

- Advantages:Reduced waste and inefficiency, improved quality, reduced inventory levels

- Disadvantages:Can be difficult to implement, may require significant investment

Just-in-Time Inventory

- Advantages:Reduced inventory costs, improved cash flow

- Disadvantages:Can be difficult to implement, may lead to stockouts

Agile Development

- Advantages:Increased responsiveness to change, faster product delivery

- Disadvantages:Can be difficult to manage, may lead to increased costs

FAQ Corner

What are the key drivers of the production revolution?

Technological innovations, including automation, computing, and robotics, have played a pivotal role in transforming production processes.

How has the production revolution impacted productivity?

Technological advancements and innovative methods have led to significant increases in efficiency and output, boosting productivity levels.

What are the potential challenges posed by the production revolution?

Sustainability concerns, job displacement, and the widening wealth gap are among the challenges that must be addressed as the revolution progresses.